Practical Math for Manufacturing

This course is designed to equip students with foundational knowledge of essential mathematical concepts used in manufacturing, including basic geometry, basic algebra, order of operations, and computation of fractions and decimals. Students will also learn how these concepts apply to measurement, machining, and design in a manufacturing environment.

Next Cohort Dates TBD

Blueprint Reading

This course develops the ability to interpret manufacturing blueprints to ensure accurate part production, inspection, and quality control in machining and fabrication settings. Students will learn to read technical drawings, identify symbols and views, and understand dimensional specifications and tolerances critical to part function and inspection. Emphasis is placed on real-world applications in machining, fabrication, and quality control environments.

Next Cohort Dates TBD

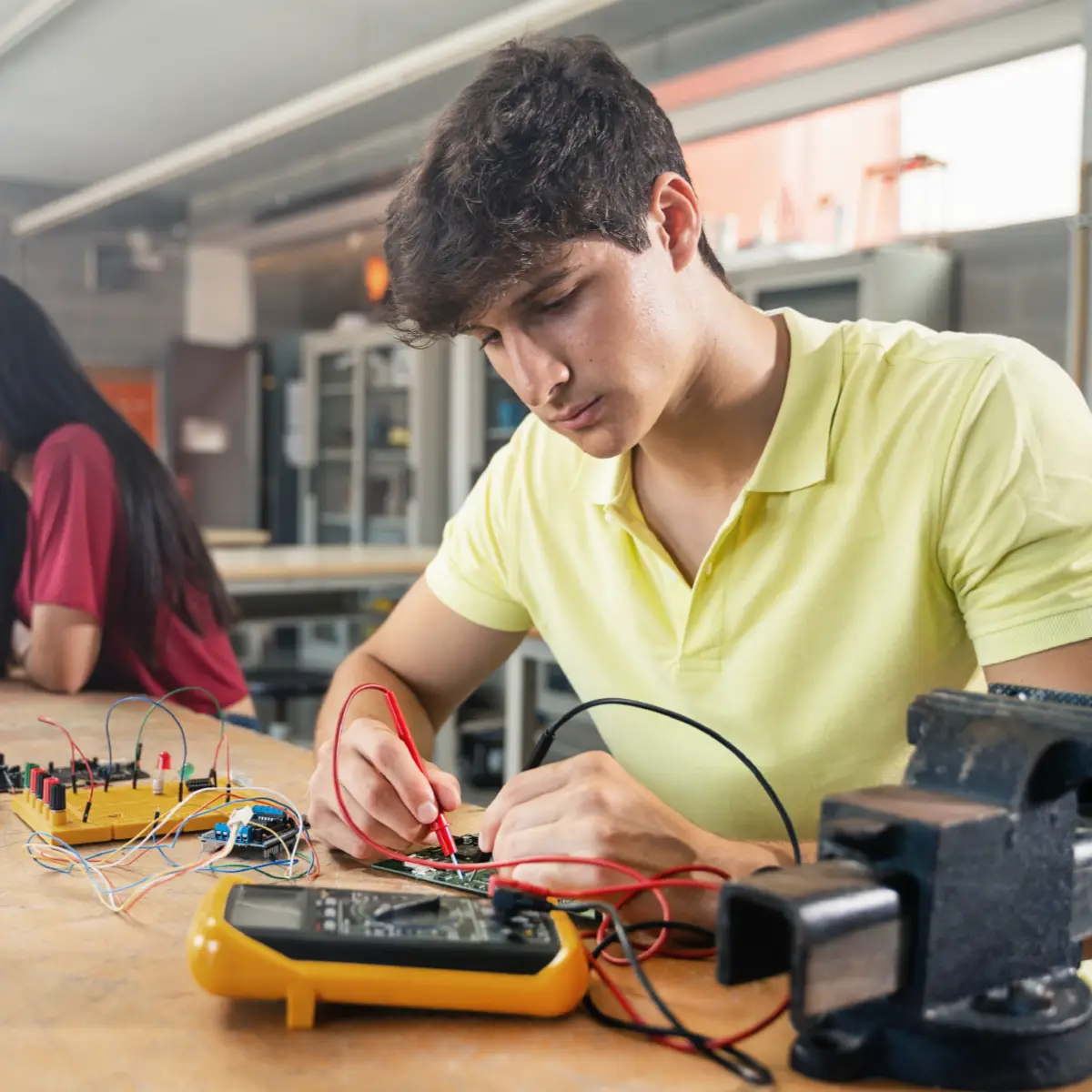

Industrial Electrical Systems

This course introduces students to the fundamentals of industrial electrical systems used in manufacturing environments. Topics include electrical safety, AC/DC theory, motor controls, relay logic, circuit analysis, and wiring practices. Students gain hands-on experience installing and troubleshooting components commonly found in industrial machinery.

February 23 – March 18, 2026

Mondays and Wednesdays

4:00 pm – 6:00 pm

CNC 1 – Fundamentals

This course introduces the fundamentals of Computer Numerical Control (CNC) machining, including machine setup, basic G-code programming, tooling, and safe operation of mills. Students gain hands-on experience producing simple parts while learning the principles of precision measurement, material selection, and machining processes.

March 3- March 26, 2026

Tuesdays and Thursdays

4:00 pm – 6:00 pm

CNC 2 – Programming

This course focuses on the principles and practices of CNC programming, including the development of G-code for milling and turning operations. Students learn to interpret technical drawings, define toolpaths, and create programs manually and using CAM software. Emphasis is placed on accuracy, efficiency, and applications in modern manufacturing environments.

COMING SOON

Spring Term (January – June 2026)

CNC 3 – Setup and Operation

This hands-on course provides students with the skills needed to safely and efficiently set up and operate CNC milling machines and lathes. Topics include machine preparation, tool selection, workholding, zeroing procedures, and running pre-written programs. Emphasis is placed on precision measurement, troubleshooting, and maintaining quality in a shop environment.

Quality Systems

This course introduces the principles of quality assurance and precision measurement in manufacturing environments. Students will learn and apply quality control methods, interpret quality standards, and operate common metrology tools including calipers, micrometers, height gauges, and CMMs. Emphasis is placed on inspection techniques, documentation, and maintaining compliance.

February 23- March 18, 2026

Mondays and Wednesdays

4pm-6pm

CMM 1 – Fundamentals

This course introduces the fundamentals of coordinate measuring machines (CMM) used in precision manufacturing inspection. Students will learn basic CMM operation, programming concepts, probe types, and how to perform simple part measurements to verify dimensional accuracy. Emphasis is on safe use, data collection, and interpretation of dimensional measurement reports.

<<SOLD OUT>>

November 3 – November 26, 2025

Mondays and Tuesdays

5:00 pm – 7:00 pm

CMM 2 – Programming

Building on foundational skills, this course covers advanced CMM programming, complex part inspection strategies, and integration of CMM data with quality systems. Students will explore multi-axis probing techniques, fixture design considerations, and software applications for dimensional analysis and reporting. Focus is on optimizing measurement efficiency and accuracy for production environments.

COMING SOON

Spring Term (January – June 2026)

Two nights per week (8 classes)

Mastercam 1

Learn the basics of CNC programming using Mastercam, including 2D geometry creation, toolpath generation, and code post-processing. Ideal for beginners looking to develop foundational skills.

Spring 2026

Mastercam 2

Advance your Mastercam skills with multi-axis toolpaths, 3D contouring, and surface machining strategies. This intermediate-level course focuses on optimizing CNC programs for complex parts and improving manufacturing efficiency.

January 12 – February 5, 2026

Mondays and Thursdays

4:00 pm – 6:00 pm

SolidWorks 1

Explore the fundamentals of 3D modeling using SolidWorks, including part design, assemblies, and basic engineering drawings. Students gain hands-on experience with parametric modeling and design intent.

SolidWorks 2

This intermediate-level course is designed for students and professionals aiming to deepen their proficiency in SolidWorks with a focus on manufacturing applications. Building on foundational skills, the course explores complex part and assembly modeling, advanced surface design, mold and tool creation, and design automation techniques. Emphasis is placed on design for manufacturing (DFM), tolerancing, simulation, and preparation for CAM and production workflows. Students engage in hands-on projects that mirror real-world engineering and fabrication challenges, producing detailed, production-ready designs and documentation. Ideal for those preparing for careers in precision machining, product design, or tooling and fabrication industries.

DATES TBD

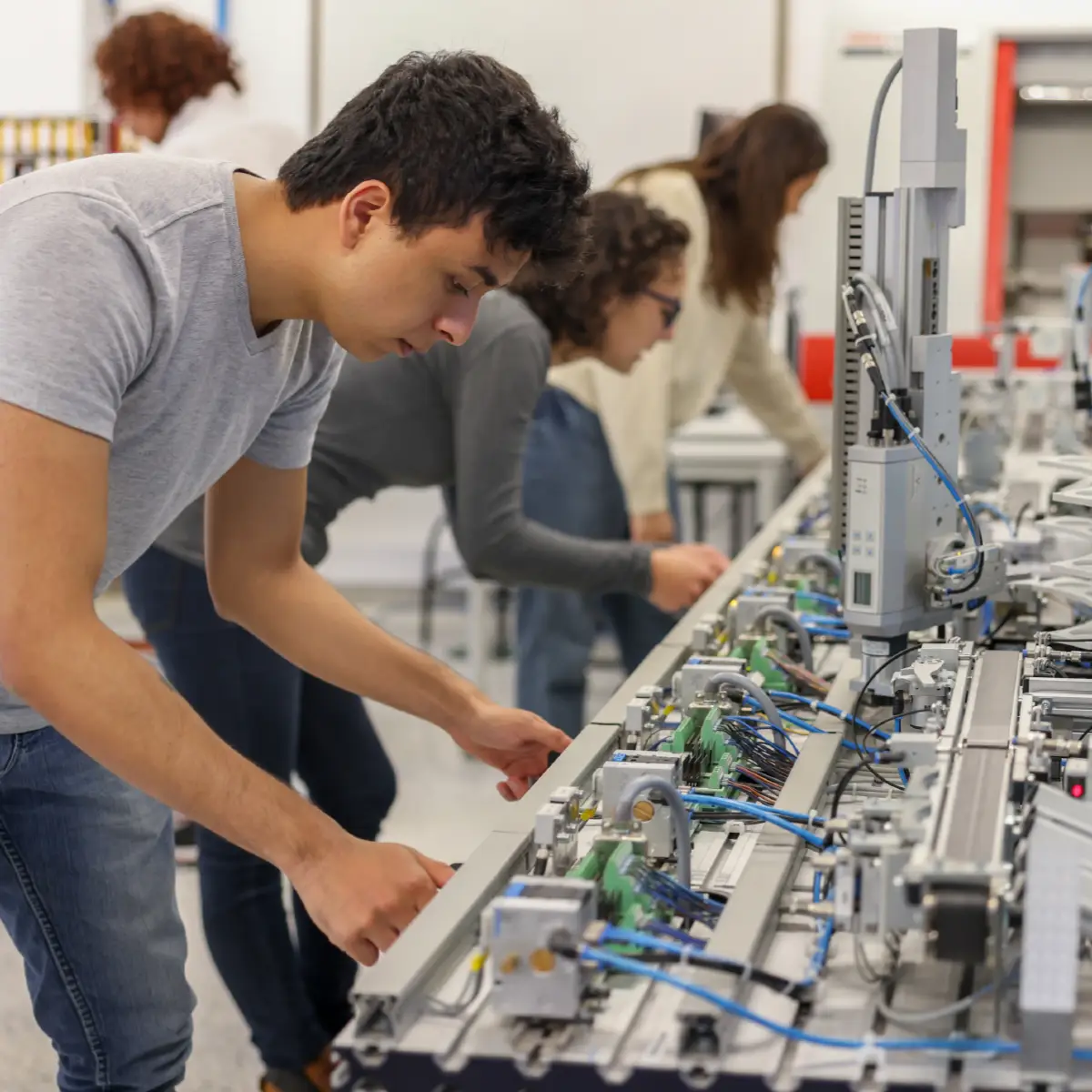

PLC 1 – Fundamentals

This course provides a foundational overview of Programmable Logic Controllers (PLCs) used in industrial automation. Students will learn about PLC hardware components, basic programming concepts using ladder logic, input/output configuration, and troubleshooting techniques. Hands-on exercises focus on designing, programming, and testing simple control systems to develop essential skills for manufacturing and process automation.

March 23rd – April 15, 2026

Mondays and Wednesdays

4:00 pm – 6:00 pm

PLC 2 – Applications

This course builds on basic PLC knowledge to cover advanced programming concepts, including timers, counters, data handling, and analog I/O processing. Students will learn to develop complex control sequences, integrate communication protocols, and troubleshoot real-world industrial automation systems. Hands-on labs focus on enhancing problem-solving skills and optimizing PLC applications in manufacturing and process control.

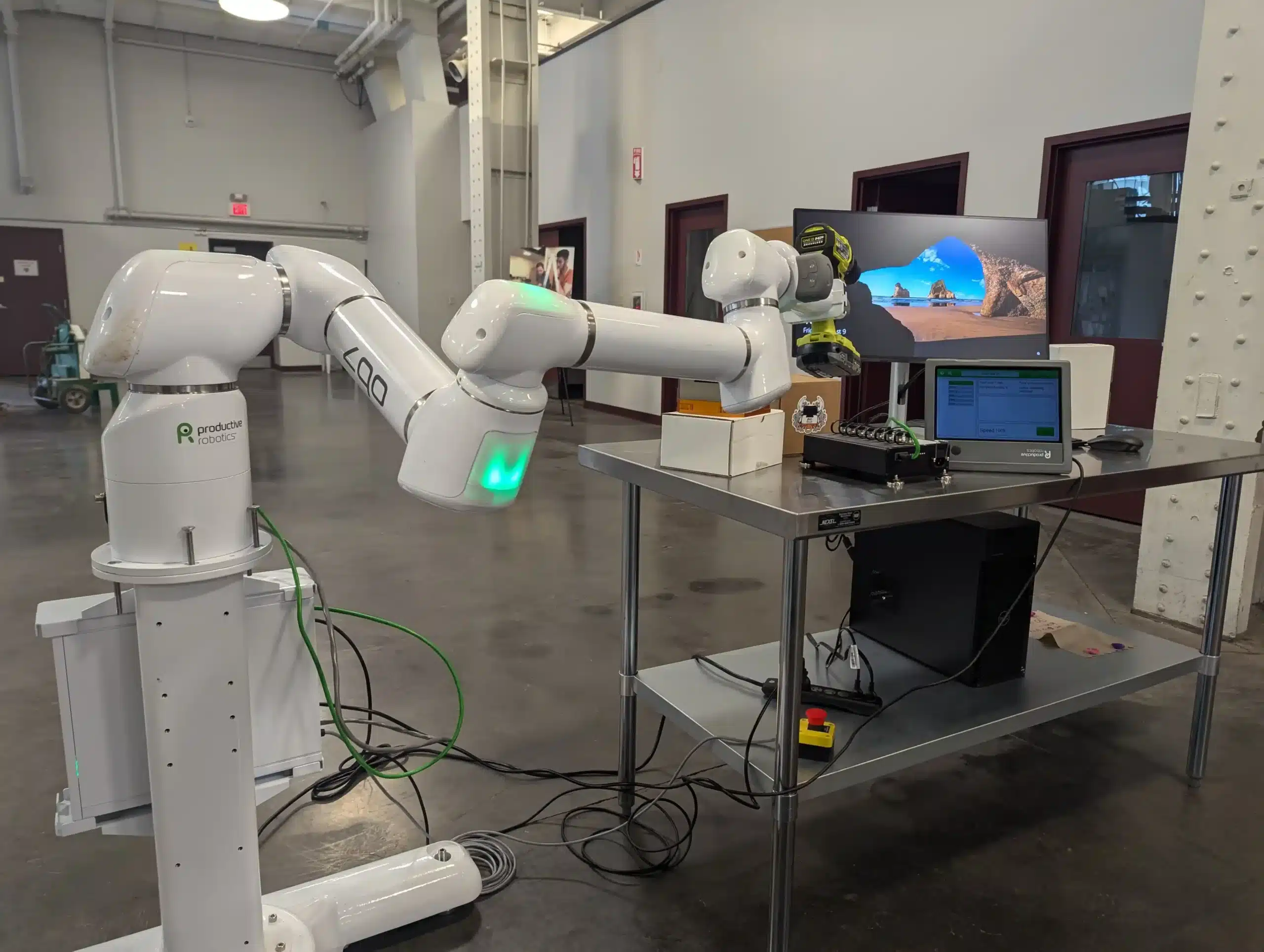

Robotics 1 – Fundamentals

This hands-on, four-week course introduces students to collaborative robot setup, safety protocols, teach pendant navigation, and basic programming techniques using FANUC robots. Learners will gain practical experience in robot movement, tool configuration, payload management, and writing simple automation programs, including pick-and-place tasks and macros for end-of-arm tooling. Ideal for beginners, this course builds foundational skills for safe and effective collaborative robot implementation.

February 10 – March 10, 2026

Tuesdays and Thursdays

4:00 pm – 6:00 pm

Robotics 2 – Programming

This intermediate-level course builds on foundational robot programming skills with a focus on logic, variables, and modular design. Students will create and manipulate sub-programs, utilize conditional logic with system registers, and integrate user frames and palletizing routines. Through hands-on labs, learners will write complex main routines, use I/O for interactive control, and apply positional offsets—equipping them for more advanced collaborative robot automation tasks in real-world settings.

April 14 – May 5, 2026

Tuesdays and Thursdays

4:00 pm – 6:00 pm

Robotics 3 – Integration

This advanced-level course prepares students to integrate collaborative robots into real-world manufacturing environments. Topics include electrical system wiring, I/O configuration, peripheral device control, and advanced program logic for complete automation cycles. Learners will build and test functional robot cells, apply safety-rated wiring standards, and utilize system monitoring tools to assess performance. Ideal for technicians and engineers, this course bridges programming and system-level integration for full-scale robotic automation.

DATES TBD

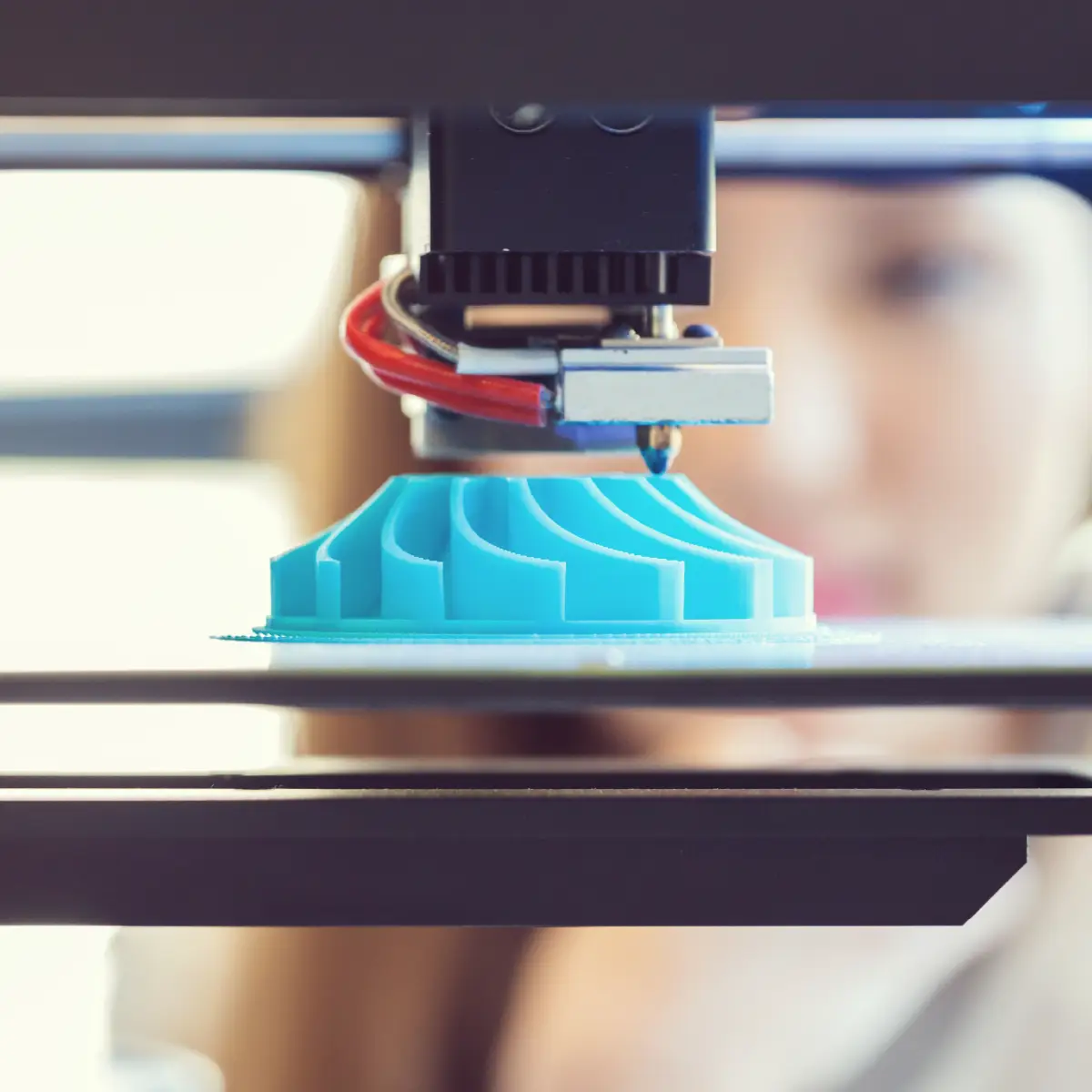

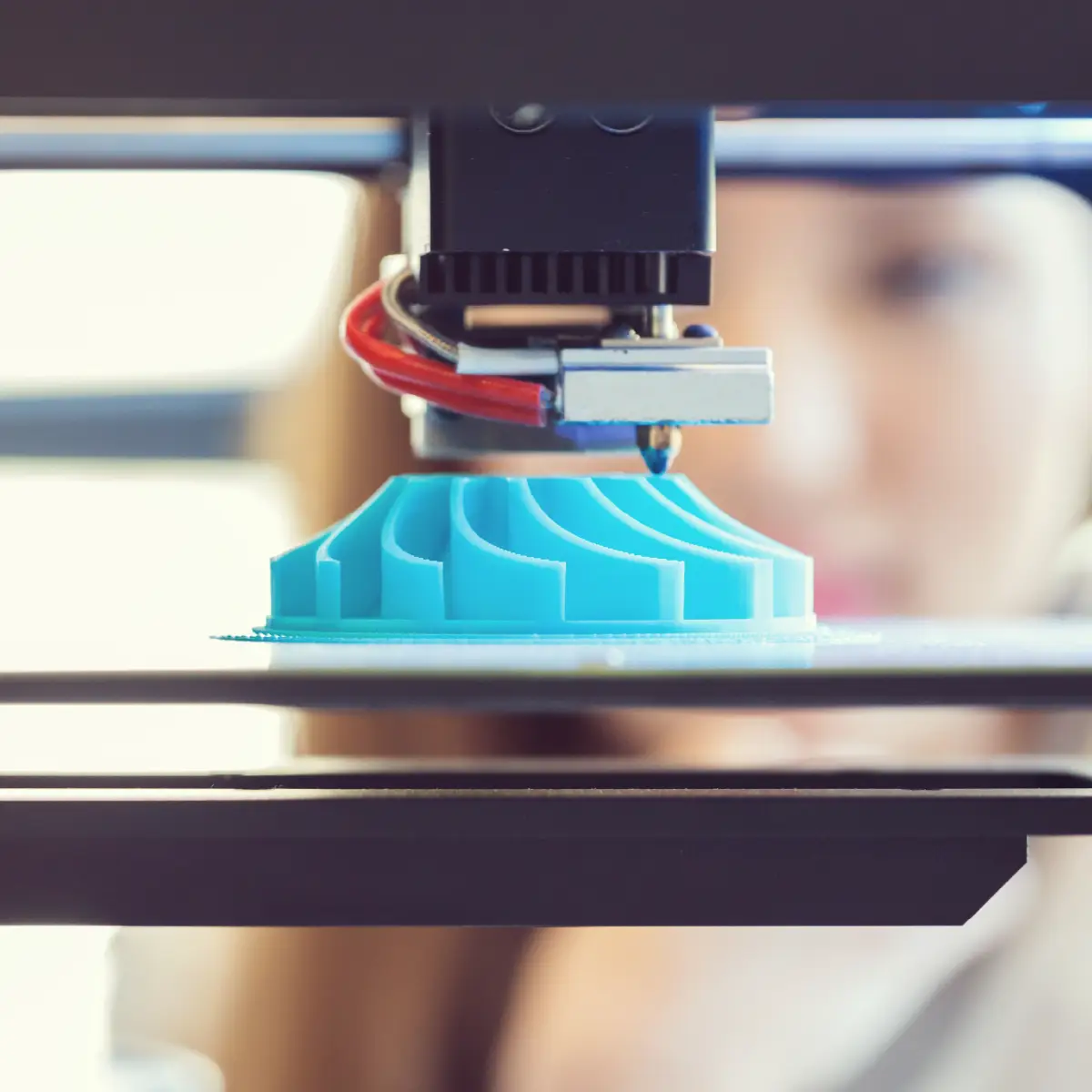

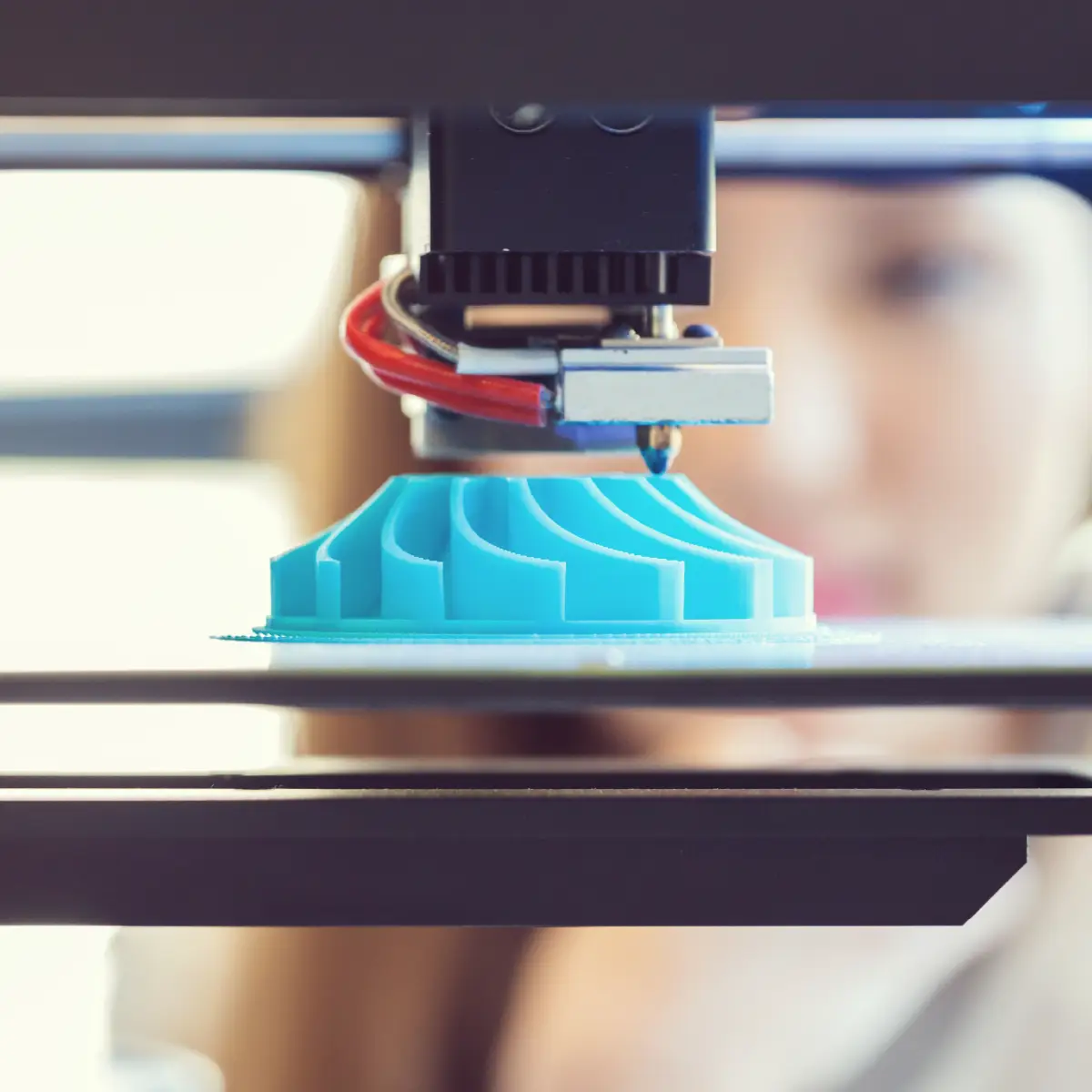

Additive Manufacturing Seminar

Discover the principles of 3D printing, materials, and applications in the manufacturing industry. This half-day, introductory course is designed for anyone curious about how 3D printing works and how it’s applied in real-world manufacturing. Participants will explore fused filament fabrication (FFF) technology and gain a high-level understanding of print design, file preparation, and the economics of printing from concept to creation. Students will also prepare, slice, and kick off their own small print projects using state-of-the-art Markforged printers. With live demonstrations, expert tips, and take-home prints, this seminar offers an accessible entry point into the world of additive manufacturing.

Additive Manufacturing 1

This course explores the principles and practical applications of additive manufacturing (3D printing) within industrial settings. Students will learn about common additive processes (FDM, SLA, SLS), material selection, design for additive manufacturing (DfAM), and post-processing techniques. Emphasis is placed on how additive technologies integrate with traditional manufacturing workflows to support rapid prototyping, tooling, and low-volume production.

Course Dates TBD

Additive Manufacturing 2

This course builds on foundational additive manufacturing skills, focusing on advanced design strategies, multi-material printing, and the integration of additive processes into full-scale production systems. Students will explore complex geometries, simulation and validation tools, and material performance considerations. Emphasis is placed on industrial case studies, quality assurance, and optimizing additive methods for cost-effective, functional part production.

Course Dates TBD

Your Leadership DNA

Your Leadership DNA is an engaging and interactive entry-level course designed for individuals ready to explore, embrace, and elevate their leadership potential. Whether you’re new to leadership, considering a leadership role, or currently leading without prior formal training, this course provides the foundational tools and self-awareness needed to lead with authenticity and confidence.

Next Course Date-TBD

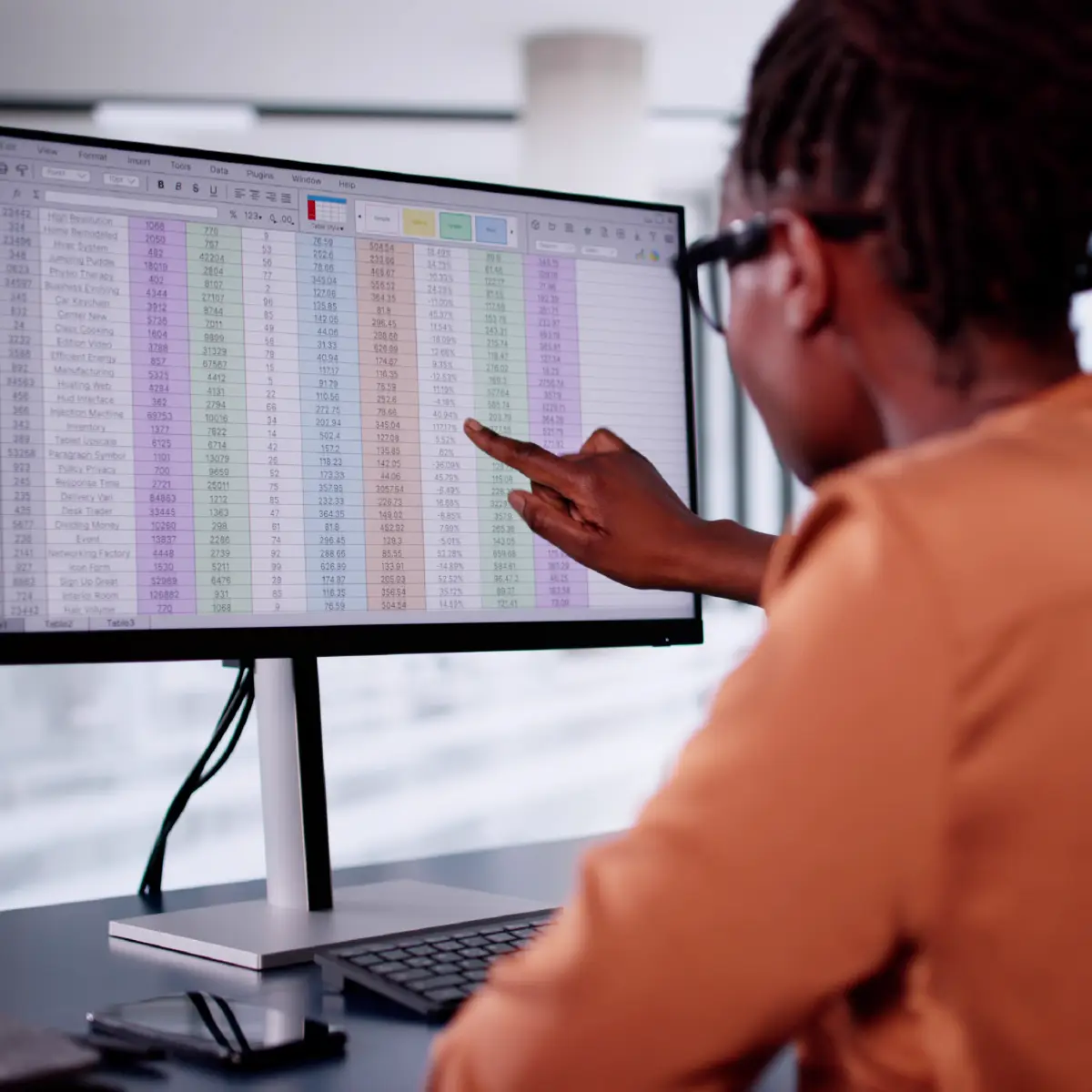

Microsoft Excel (Level 1)

Participants will develop fundamental Excel skills, including setting up spreadsheets, entering and manipulating data, and using AutoFill to save time. They will also learn how to print spreadsheets correctly, create basic formulas and functions, and edit and format data efficiently. By the end of the course, students will be equipped to manage large workbooks and use Excel’s core features to improve productivity.

January 21st, 2026

9:00 am-3:00 pm

Microsoft Excel (Level 2)

Participants will learn to summarize data with PivotTables, clean data using text functions, and automate tasks with logical functions like AND, IF, and OR. The course also covers lookup functions such as VLOOKUP and INDEX/MATCH, converting data into Excel tables, and adding objects like logos to workbooks. Additionally, participants will explore data protection techniques. By the end, participants will be equipped to handle more advanced tasks and increase productivity in Excel.

Next Course TBD

Microsoft Excel (Level 3)

Participants will learn to use data validation, create macros, and apply tools like scenarios and goal seek for “what-if” analysis. The course also covers auditing worksheets, working with external data, and inserting hyperlinks. Participants will learn to manage multiple workbooks, create forms, and get an introduction to Visual Basic for automating tasks. By the end, participants will be proficient in advanced Excel techniques to enhance productivity and data management.

March 26, 2026

9am-3pm