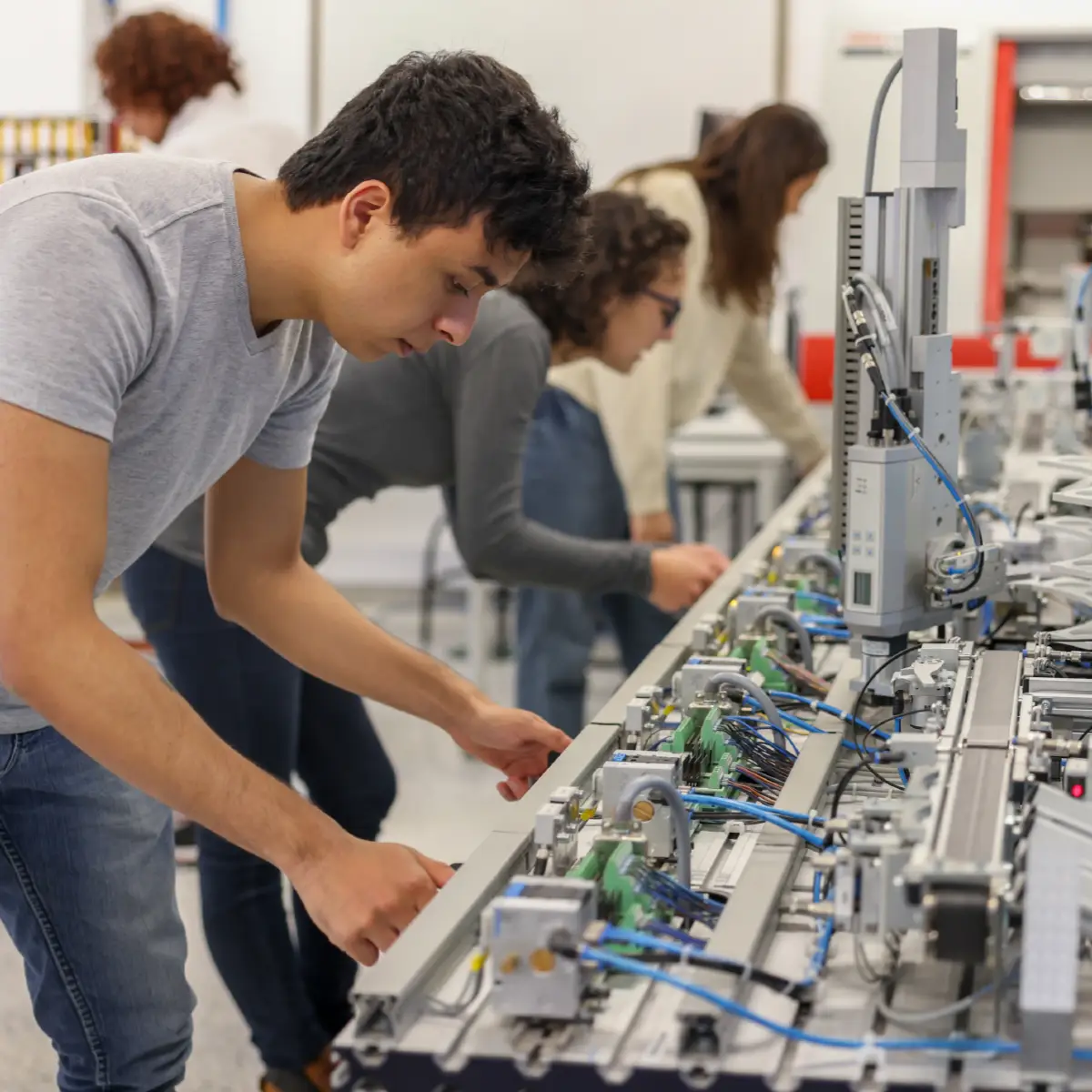

Automation & Controls courses at ALIC equip students with foundational and practical knowledge of industrial automation systems. Through a series of courses ranging from Programmable Logic Controllers to Robotic Automation, Collaboration, and Integration, learners work with sensors, actuators, robotic arms, PLCs, and HMI systems to design and operate industry-standard automated setups that mirror real production lines.

Students gain valuable hands-on experience in configuring integrated systems, troubleshooting, and optimizing performance. Projects and simulations reinforce the connection between theory and real-world implementation, helping learners understand how to use automation and controls to improve process efficiency and production quality. By the end of the series, students develop both the technical and problem-solving skills needed to design, integrate, and maintain modern automation systems in evolving industrial settings.