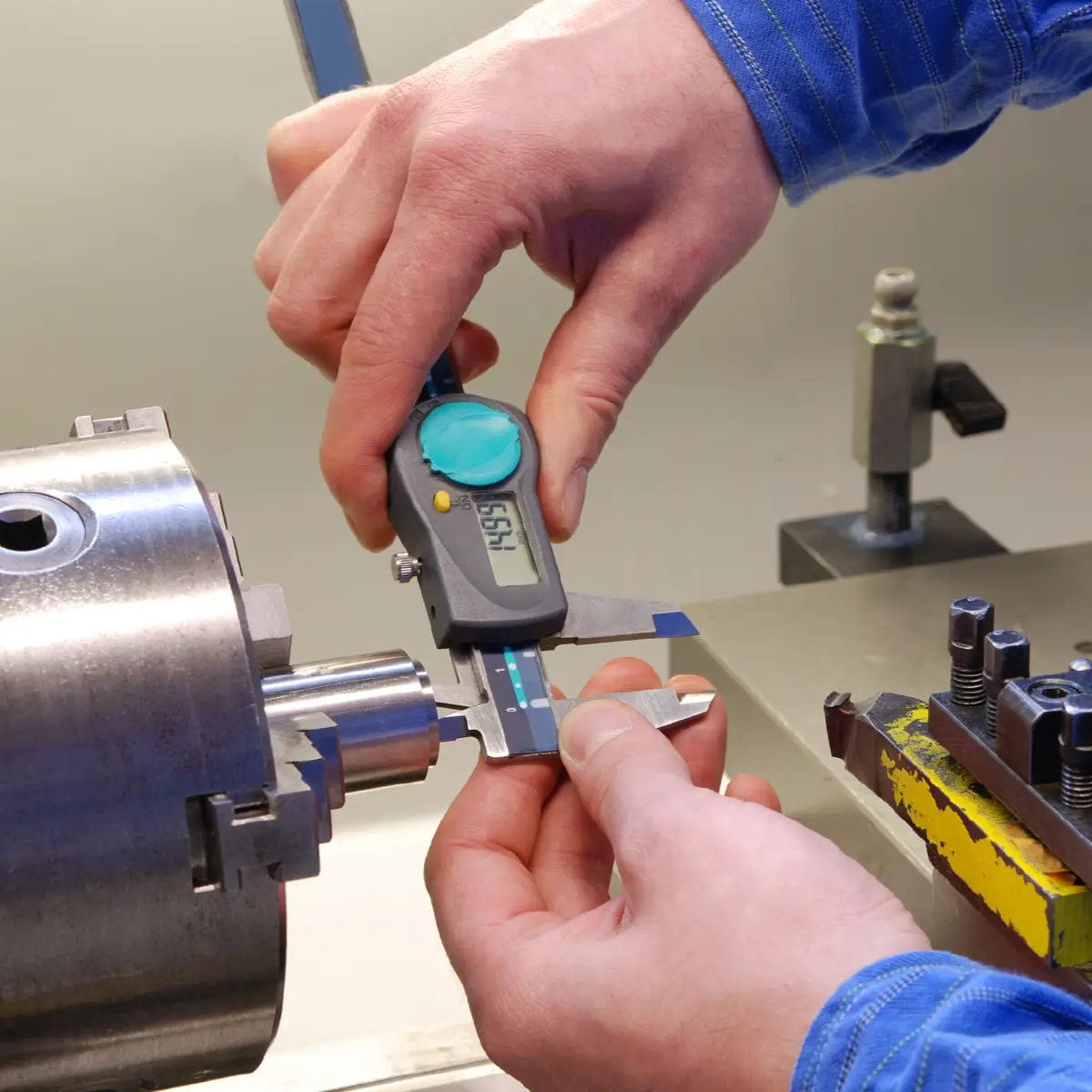

The Operational Excellence microcredential empowers students with the tools, methodologies, and mindset to drive quality improvement and efficiency in manufacturing environments. Through focused instruction in Six Sigma and SPC Fundamentals and Quality Systems and Metrology, learners develop a practical understanding of data-driven decision-making, process improvement, and rigorous quality assurance practices. They explore key Six Sigma principles such as DMAIC, use control charts and statistical tools to evaluate process stability, and perform root cause analysis to identify and solve real-world quality challenges. Complementing this is a deep dive into quality systems, including ISO standards, inspection techniques, and calibration practices using tools like calipers, micrometers, and coordinate-measuring machines (CMMs).

By the end of the microcredential, students are prepared to actively support and lead quality initiatives on the shop floor. They gain experience applying SPC software, conducting audits, interpreting measurement data, and presenting improvement plans backed by evidence. Hands-on projects, mock audits, and simulations reinforce the application of theory in realistic manufacturing settings, giving learners the confidence to promote operational efficiency, reduce waste, and sustain high standards of quality. This microcredential is ideal for those looking to elevate their impact in quality control, continuous improvement, or process management roles within the manufacturing sector.