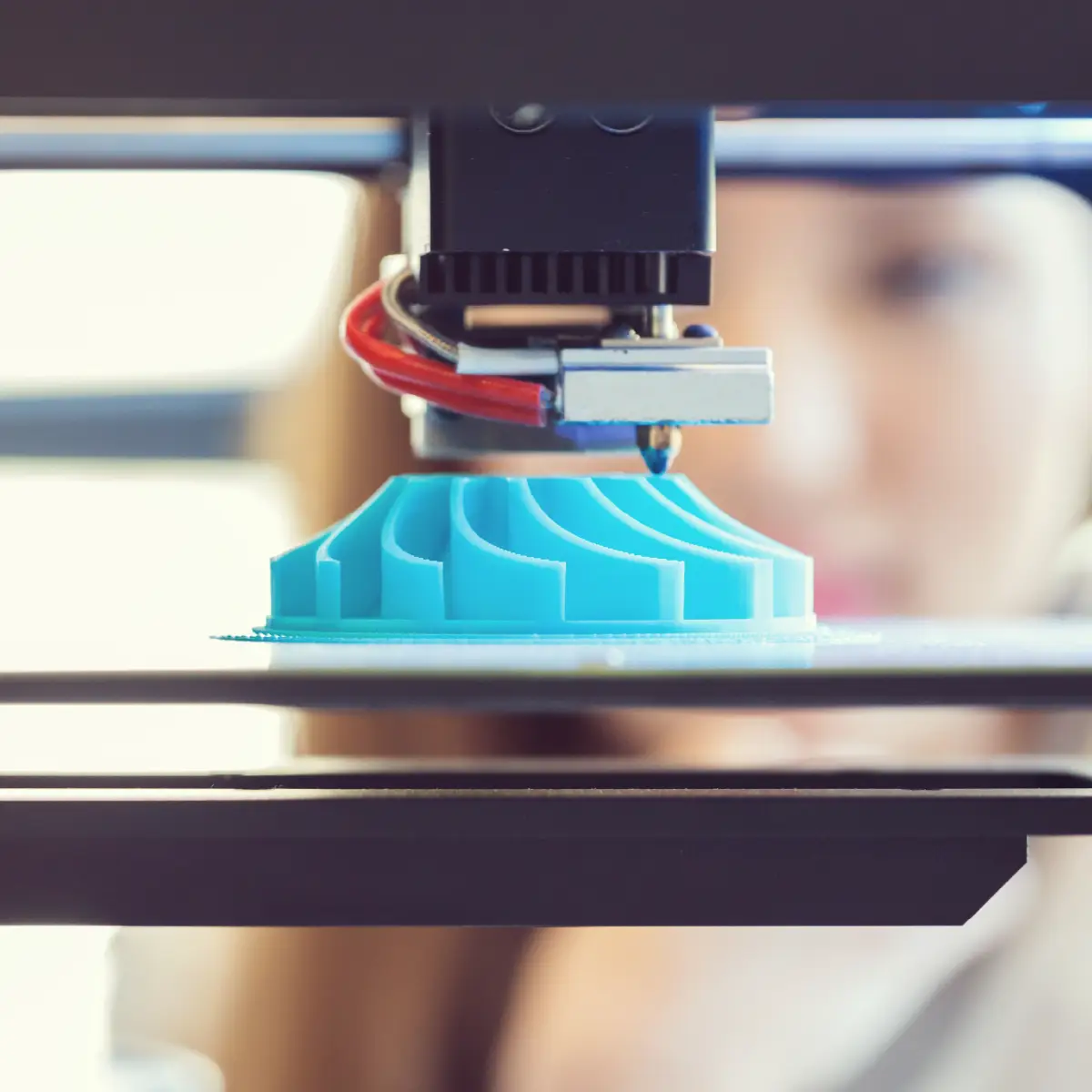

Manufacturing Innovations courses at ALIC introduce students to cutting-edge technologies transforming the future of industrial production. Beginning with the Additive Manufacturing series, learners gain hands-on experience with 3D printing technologies — developing skills to design, slice, calibrate, and troubleshoot printed parts. Students explore the performance characteristics of various materials and examine real-world applications of additive manufacturing across multiple industries. Through practical projects, students build functional prototypes, fixtures, and industrial-grade parts, reinforcing their understanding of how additive manufacturing can drive customization, efficiency, and cost-effective production.

With the upcoming Manufacturing Material Science course expanding this focus, learners will gain a deeper view of how materials and advanced fabrication technologies interact, preparing them to lead and adapt in dynamic, tech-forward manufacturing environments.